Z-BRAIN OPS

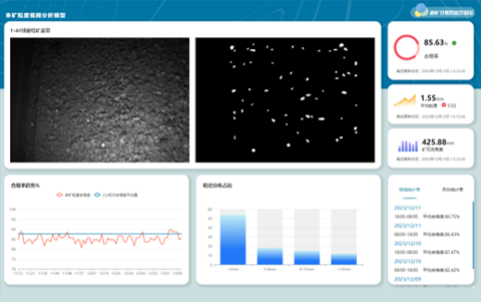

The Intelligent ore size analysis system is designed to provide efficient and accurate ore size data and enable comprehensive monitoring and analysis of the entire mine area. The particle size identification of concentrator usually adopts manual screening method, which is complicated, time-consuming and low precision, and difficult to guide production operation in time. The customer's demand is to grasp the pass rate of granularity fed to the grinding belt and the proportion of ore distribution of different particle grades in real time, and adjust the subsequent operations in time.

The ore particle size intelligent analysis system includes a set of Ops-MIND artificial intelligence mining analysis server and several sets of OpsCAM on-site image acquisition stations, which can detect ore particle size in real time through 5G or LAN connection. The system supports docking with third-party systems to provide on-site data support for the digital mine of the whole process.

OPS-MIND Intelligent Mine Integrated Cabinet: The cabinet integrates advanced data processing and analysis functions to monitor ore particle size in real time and provide multi-dimensional data analysis reports. Through artificial intelligence technology, key parameters such as the size and shape of ore particles can be quickly and accurately identified and analyzed.

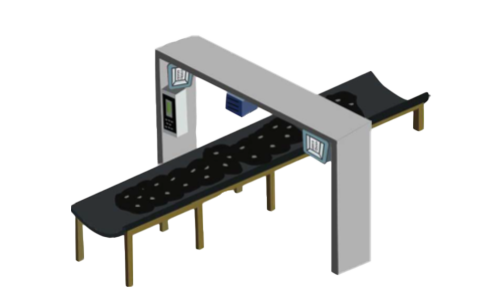

OPS-CAM on-site image acquisition station: equipped with multiple sets of high-definition cameras, covering key locations in mining areas to capture image data during ore transportation in real time. These image data are transmitted to the OPS-MIND cabinet via 5G or LAN connection to provide reliable data support for subsequent analysis.

OPS-IOT Data Connection Internet of Things interface: Through this interface, users can view ore particle size data and analysis results in real time at the OPS-SDS operation station. At the same time, it also supports docking with third-party systems to achieve data sharing and interaction, providing a broader application space for mine digital management.

Product advantages:

Efficient and accurate: With the help of advanced artificial intelligence and image recognition technology, the rapid and accurate analysis of ore particle size is achieved, which greatly improves the efficiency and accuracy of data processing.

Efficient and accurate: With the help of advanced artificial intelligence and image recognition technology, the rapid and accurate analysis of ore particle size is achieved, which greatly improves the efficiency and accuracy of data processing.

Comprehensive monitoring: OPS-CAM field image acquisition station covers the key locations of the mining area, realizing the comprehensive monitoring of the entire mining area, discovering and solving problems in time, and improving the level of production management.

Intelligent interconnection: Through the OPS-IOT interface, intelligent interconnection and data sharing between devices are realized, providing users with a more convenient and efficient operation experience.

Application scenario:

The intelligent ore particle size analysis system is widely used in all kinds of mining enterprises, including metal mines, coal mines, etc., and provides reliable data support and intelligent solutions for mine production management.

In the construction of digital mines, the system will become an important technical equipment to help mining enterprises to improve production efficiency, reduce costs and ensure safe production.