Z-BRAIN BML

Grinding operation is the most energy consuming part of concentrator. The prediction and control of ball mill operation state is the key to improve the efficiency of concentrator. At present, the field usually relies on workers to judge according to the sound of the ball mill, which has large errors and low efficiency.

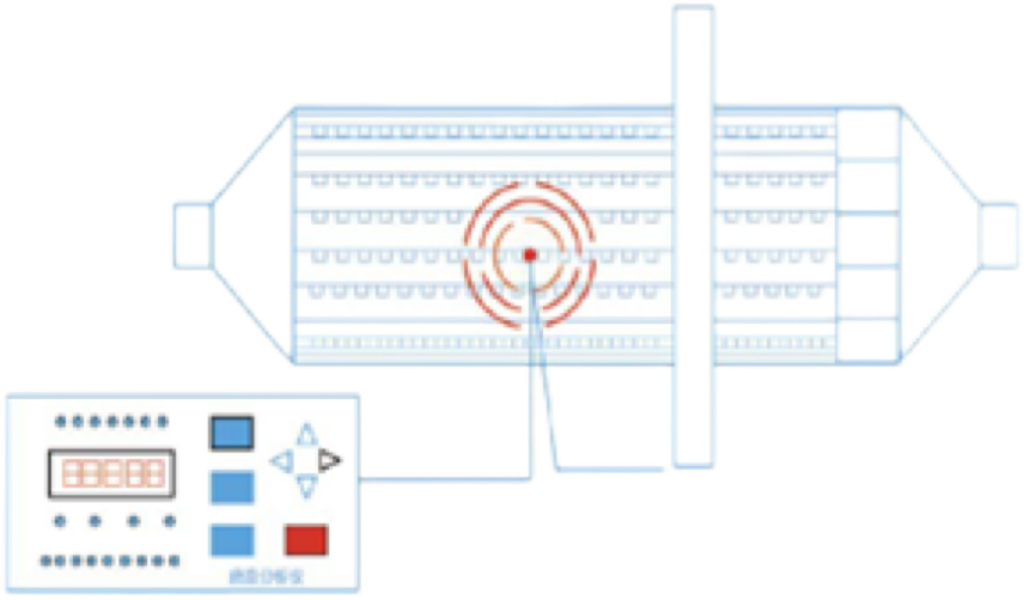

The intelligent prediction system of ball mill load includes OpsMIND artificial intelligence mining area analysis server and OpsGSD grinding sound detection system, which can realize intelligent analysis and control of ball mill load through 5G or LAN connection. The system adopts the PCC-PSO-SVM model to monitor and predict the load state of the ball mill in real time, predict and alarm the abnormal situation, and quickly adjust to the optimal load state without relying on manual experience.

Function introduction:

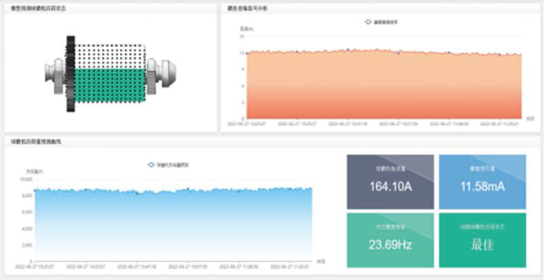

Intelligent load prediction: The advanced PPCA -PSO-SVM model is adopted to predict the load of the ball mill intelligently by monitoring the sound and other operating parameters of the mill in real time.

Abnormal early warning: Provides real-time early warning for abnormal load conditions to help adjust operating parameters in time to avoid production problems caused by high or low load.

Abnormal early warning: Provides real-time early warning for abnormal load conditions to help adjust operating parameters in time to avoid production problems caused by high or low load.

Automatic adjustment: The system can automatically adjust the running state of the ball mill according to the predicted results to ensure that the equipment is always in the best load state and improve production efficiency.

Unmanned control: to achieve unmanned control of the load state of the ball mill, reduce the dependence on manual experience, and reduce the labor intensity of the operator.

Data recording and analysis: Automatically record load data and provide detailed historical data analysis reports to assist decision-making and optimize production processes.