Z-BRAIN FCG

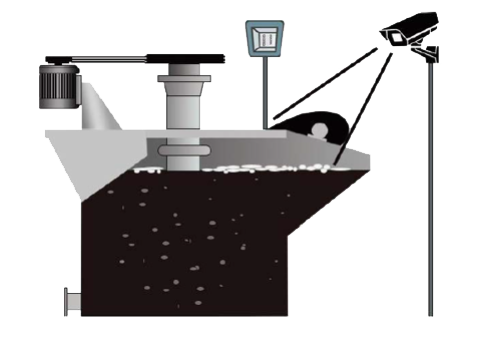

The flotation process mainly relies on workers to observe the characteristics of flotation foam and sampling and testing, which is subjective and low frequency, and can not obtain reliable results in real time. Customers need to reduce human interference and predict flotation concentrate grades in real time.The intelligent prediction system of flotation concentrate grade includes OpsMIND artificial intelligence mining area analysis server and OpsCAM on-site image acquisition station. Multi-dimensional deep spatiotemporal convolution and multi-modal time series deep learning algorithms are used to predict concentrate grade quickly and accurately.

Function introduction:

Real-time grade prediction: Multi-dimensional deep space-time convolution and multi-modal time series deep learning algorithm are used to predict the grade of flotation concentrate in real time.

High accuracy:

The prediction accuracy reaches more than 90%, providing reliable grade prediction results and reducing production losses caused by grade fluctuations.

Foam characteristics analysis:

The system captures flotation foam images through OpsCAM on-site image acquisition station, analyzes foam characteristics, combines chemical composition data, and accurately predicts grade.

Automatic adjustment suggestions:

Based on the predicted results, the system can automatically provide production parameter adjustment suggestions to help optimize the flotation process and improve the recovery rate of the concentrate.

Reduce manual intervention:

The system reduces the dependence on manual experience, realizes the intelligent and automatic control of the flotation process, and improves production efficiency and stability.